Lightweight Aerospace RF Coaxial Cables

Rising Demand for Lightweight Aerospace Coaxial Cable Technology

Aerospace engineers are consistently being challenged to design lighter aircraft. Saving weight is a top priority in both forward-fit and retrofit designs to reduce materials and fuel costs, while increasing payload. One major way to save aircraft weight is by installing lightweight cables. PIC has designed a line of lightweight cables that address industry demands for weight-saving technology and its requirement for high-performance, reliable interconnects. PICMates ULTRALITE RF Cable is an extension of its 50-ohm RF coaxial cable line and is engineered to provide significant cable weight savings.

ULTRALITE RF Cables Offer a Robust Solution for a Variety of Advanced Electronic Applications:

- Communications: Satcom, Iridium, Cellular, VHF, UHF and HF

- Navigation: GPS, Radio Altimeter, DME, VOR and Marker Beacon

- Collision Avoidance: ADS-B, TCAS, TAS, ACAS and Skywatch

PICMATES ULTRALITE CABLES Save Aircraft Cable Weight

The ULTRALITE RF Cable family has been rapidly adopted by major aircraft and avionics OEMs in response to the rising industry demand for weight-saving cables. These lightweight, flexible cables offer significant weight savings over competitors and industry-standard RG cables:

UH25107 IS 81% LIGHTER THAN RG211 & 33% LIGHTER THAN CABLES OF SIMILAR SIZE AND PROPERTIES

UH22089 IS 59% LIGHTER THAN RG393 & 62% LIGHTER THAN CABLES OF SIMILAR SIZE AND PROPERTIES

UH67163 IS 80% LIGHTER THAN RG393 & 55% LIGHTER THAN CABLES OF SIMILAR SIZE AND PROPERTIES

UH44193 IS 56% LIGHTER THAN RG142 & 63% LIGHTER THAN CABLES OF SIMILAR SIZE AND PROPERTIES

| Coaxial Cable | Weight lbs/100 ft (kg/100 m) |

Loss @ 1.0 GHz dB/100 ft (dB/100 m) |

Bend Radius in (mm) |

Cable O.D. in (mm) |

Shielding Effectiveness (dB) |

|---|---|---|---|---|---|

| UH25107 | 12.0 (17.9) | 2.8 (9.2) | 2.50 (63.50) | 0.445 (11.303) | -110 |

| Cable of Similar Size and Properties | 18 (8.2) | 3.1 (10.2) | 3.00 (76.2) | 0.485 (12.319) | -90 |

| UH22089 | 7.2 (10.7) | 3.5 (11.5) | 1.70 (43.18) | 0.345 (8.763) | -110 |

| Cable of Similar Size and Properties | 19 (8.6) | 3.6 (11.8) | 2.26 (57.40) | 0.452 (11.481) | -90 |

| UH67163 | 3.4 (5.1) | 6.2 (20.3) | 1.20 (30.48) | 0.227 (5.766) | -110 |

| Cable of Similar Size and Properties | 7.5 (3.4) | 6.3 (20.7) | 1.60 (40.64) | 0.313 (7.950) | -80 |

| UH44193 | 1.9 (2.9) | 10.4 (34.1) | 0.80 (20.32) | 0.152 (3.861) | -110 |

| Cable of Similar Size and Properties | 4.3 (2.0) | 12.2 (40.0) | 1.00 (25.4) | 0.195 (4.953) | -90 |

| RG211 | 64.1 (95.4) | 4.5 (14.8) | 3.60 (91.44) | 0.730 (18.542) | -50 |

| RG393 | 17.5 (26.4) | 7.7 (25.2) | 1.95 (49.53) | 0.390 (9.906) | -75 |

| RG142 | 4.3 (6.4) | 13.4 (44.0) | 1.00 (25.40) | 0.195 (4.953) | -75 |

Table 1: PICMates ULTRALITE Cable and RG Cable Comparison

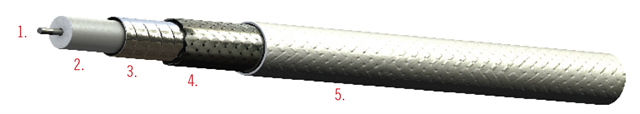

Innovative Cable Construction

1. Conductor

UH67163, UH25107 and UH22089 use a Silver Plated Copper Clad Aluminum (SPCCA) conductor to increase weight savings. SPCCA conductors are 69% lighter compared to copper conductors of the same gauge. Based on its size, UH44193 uses Silver-Plated Copper Clad Steel. Steel conductors are 11% lighter compared to copper conductors of the same gauge.

2. Dielectric

ULTRALITE RF cables use either an expanded extruded Polytetrafluoroethylene (PTFE) or tape-wrapped PTFE dielectric. The dielectrics have a high Velocity of Propagation (VoP) which lowers the cable’s insertion (dB) loss, while still maintaining a strong composition. This dielectric also saves weight and increases flexibility.

3. Inner Shield

ULTRALITE RF cables use a Silver Plated Copper spiral (helically) wrapped shield. With this design, the -110 dB shielding effectiveness is the same as a semi-rigid coaxial cable (solid copper tube), such as RG405. This is significantly higher than the standard -75 dB for dual braided shields used in RG cables, and -90 dB for cables with a foil and outer braid shield. The spiral-wrapped shield provides 100% coverage compared to flat braided shields. This shield design increases the cable’s shielding effectiveness and lowers its dB loss.

4. Outer Braid

ULTRALITE RF cables use a Silver Plated Copper Clad Aluminum (SPCCA) outer braid. This braid is designed to minimize dB loss and its lightweight material contributes to weight savings.

5. Outer Jacket

ULTRALITE RF cable jackets are made of high-temperature, white ethylene tetrafluoroethylene (ETFE). This material allows cables to be used and stored in high-temperature environments. They are chemical resistant, abrasion resistant, and meet the FAA flammability requirements 14 CFR Part 25.869 (a)(4) Amdt 25-113 Appendix F Part 1 (a)(3). Each cable is also laser markable to streamline and simplify the labeling process.

RFMATES ULTRALITE Connectors

The ULTRALITE RF cable family includes a variety of matching connectors, including a full line of M39012-style RF connectors. Pairing ULTRALITE cables and connectors provide a robust interconnect solution by optimizing electrical performance and increasing weight savings. The connectors also improve termination, installation, maintenance and reliability. To ensure proper field installation and termination, crimp die sets are available for the connectors. In addition, PIC Wire & Cable offers complete certified cable assemblies to streamline the installation process.

Tested Cable Reliability

ULTRALITE RF cables and connectors passed rigorous EWIS testing. Our EWIS testing includes Vibration, Shock, Thermal Shock, Aging Stability, Flammability, Smoke & Toxicity testing per Airbus ABD0031 and many more tests to ensure the cables and connectors are robust enough for their rugged aerospace and defense applications. A concentrated load testing per MIL-T-81490 was conducted to demonstrate ULTRALITE cables have better compressive resistance compared to similar-sized cables. In addition, the ULTRALITE line is Skydrol resistant, RoHS compliant, meets the FAA flammability requirements 14 CFR Part 25.869 (a)(4) Amdt 25-113 Appendix Part 1 (a)(3), and complies with MIL-C-17 as applicable. EWIS tests and qualification test reports are available by request.