Enhance Aerospace Signal Integrity with MACHFORCE Connectors

Safeguarding Performance and Reliability with MACHFORCE

Ensuring signal integrity is a formidable challenge in today's aerospace and defense applications. With the rapidly evolving avionic systems in the industry, there is a growing demand for faster, more reliable, and secure data transmission. Managing your system's impedance, insertion loss, crosstalk, grounding, EMI, and signal reflections is paramount to optimizing signal integrity in mission-critical operations.

The MACHFORCE connector offers a solution to these complex connectivity issues. With superior electrical performance, MACHFORCE’s innovative High-Speed Module (HSM) sets a new standard by ensuring impeccable signal integrity.

MACHFORCE HIGH-SPEED MODULE (HSM)

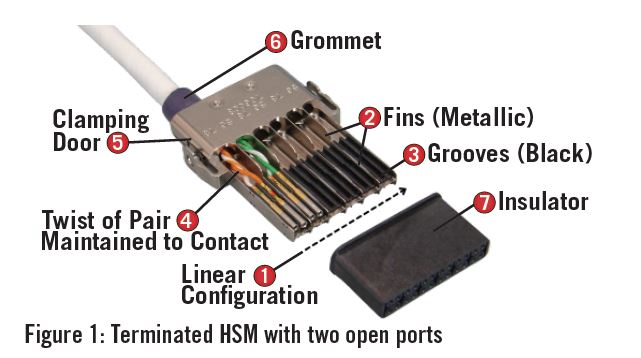

This game-changing HSM was engineered to help ensure the ability of your system to manage interference and provide data integrity, reliability, and effectiveness in critical aerospace and defense systems through its design below (see Fig. 1).

Figure 1: Terminated HSM with two open Ports

1. LINEAR CONFIGURATION

Modules are configured in a linear pattern to improve electrical performance by maintaining consistent impedance, which reduces signal reflection and insertion loss. This space-saving design allows for more ports to be placed in a connector row compared to other D-38999 connectors on the market. MACHFORCE connectors deliver 10 ports in a size 25 connector and 4 ports in a size 17.

2. FINS

Vertical fins in the HSM create a shield between the twisted pairs, isolating each data pair from the next by reducing cross talk in your system.

3. GROOVES

Grooves in the HSM snap each contact into place to secure your connectivity in high-vibration environments. These grooves also isolate each wire in the data pair to maximize cross-talk protection.

4. TWIST OF PAIRS MAINTAINED TO CONTACT

Sections where the cable runs are straight and parallel are susceptible to crosstalk. To prevent this, the HSM ensures that every twisted pair maintains its twist right up to the contact, achieving unmatched impedance control.

5. CLAMPING DOOR

Under the clamping mechanism of the HSM, the cable’s shielding is secured and grounded to the HSM. When the HSM is inserted into the MACHFORCE connector body, the grounding connection is maintained throughout the entire solution (see Fig. 2). This contributes to better isolation of the twisted pair’s signals.

6. GROMMET

The rubber grommet, in conjunction with the HSM clamping door, provides strain relief to the cable and applies constant pressure to the cable’s shielding, maintaining contact with the HSM.

7. INSULATOR

The insulator maintains proper spacing for the 22D contacts when mated. When the HSM is inserted into the connector body, the insulator electrically isolates the contacts from the connector body (see Fig. 2). The dielectric constant of the insulator's material also boosts signal integrity.

Figure 2: HSM Inserted into MACHFORCE Connector

TESTed & VALIDATED PERFORMANCE

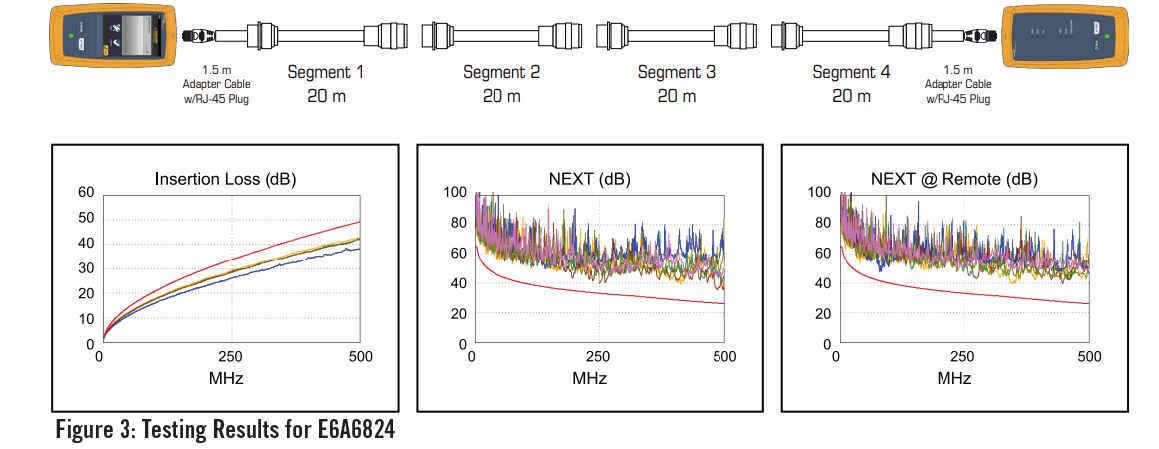

By prioritizing signal integrity in the design, implementation, and maintenance of aerospace and defense systems, you can ensure the reliability, resilience, and security needed for mission-critical operations.

Overall, the MACHFORCE high-speed module is a game-changer, enabling the design of applications that were previously not possible. For example, we designed 24 & 26 AWG CAT6a assemblies with 5 connection breaks and passed a CAT6a channel test. The 24 AWG assembly maintained 10Gb signals and achieved lengths greater than 270 ft. (80m), while the 26 AWG cable passed at lengths up to 230 ft. (70m). Both assemblies showcased low insertion loss at these distances.

Figure 3: Test Results for E6A6824

Begin building your custom MACHFORCE Connector with our user-friendly online configurator.

Build a MACHFORCE Assembly

Need help getting started? No problem! Our dedicated team is here to assist you.

Contact us for personalized assistance